Milling cutters

STARTER MILLING CUTTER – FS

FS starter milling cutter is designed for lowering the whipstock and initial milling of the ‘window’ in the production column.

MILLING CUTTER «NEEDLE» - 2FZ

Needle type milling cutter is designed and tested for milling MSHF ports, and is also designed for drilling cement bridges, sand plugs, technological equipment of casing string, packer plugs, metal objects located in the bottom of the well along the entire section

END-SIDE MILLING CUTTER – FT

End milling cutter is designed for destruction of metal objects, cement stone and cemented metal objects along the entire cross-section of wells during repair and restoration work in oil, gas and geological exploration wells.

END GEAR MILLING CUTTER - 2FTZ (COMBINED)

End milling cutters are designed for the destruction of cement stone, sand plugs and cemented metal objects along the entire cross-section of wells during repair and restoration work in oil and gas wells, as well as drilling the technological equipment of packers and plugs, including multistage hydraulic fracturing (MSHF) ports.

CONE CASING MILLING CUTTER – FKK

Cone casing milling cutter is designed for milling the walls of casing pipes, leveling geometric parameters; for crumples removal and scuffing; removing cement and paraffin deposits; working out perforation intervals.

CONE SPIRAL CASING MILLING CUTTER – FKKS

Cone spiral casing milling cutter is designed for milling the walls of casing pipes, leveling geometric parameters; for crumples removal and scuffing; removing cement and paraffin deposits; working out perforation intervals.

REINFORCED END-SIDE MILLING CUTTER (BARRAKUDA TYPE) - 28FT6-ST

Reinforced end milling cutter with carbide plates (Barracuda type) is designed for the destruction of metal objects, cement stone along the entire section of the well during repair and restoration work. The cutting surface of the milling cutter has a segmented design, with each segment reinforced with carbide teeth.

CONCAVE END-SIDE MILLING CUTTER – FTV

Concave end milling cutter is designed for destruction of metal objects, cement stone and cemented metal objects along the entire cross-section of wells with the centering of loose milling objects relative to the milling cutter during repair and restoration work in oil, gas and geological exploration wells.

REINFORCED END-SIDE MILLING CUTTER

Reinforced end milling cutter is designed for the destruction of metal objects, cement stone along the entire section of the well during repair and restoration work.

EXPANDING MILLING CUTTER

Expanding milling cutter is included in the composition of the bottom hole assembly (BHA) for well templating and cutting a window in the casing.

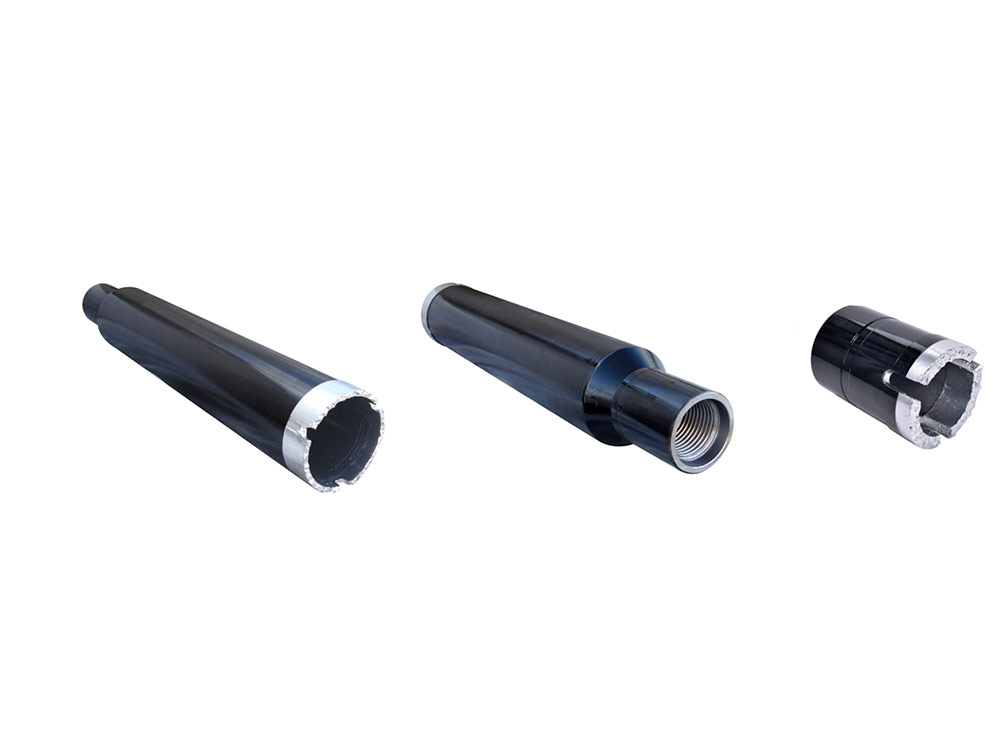

RING MILLING CUTTER

Ring milling cutter is designed for the destruction of metal objects, cement stone and cemented metal objects in the annular space between the well wall or casing and the elements of the elevator or drill strings during repair and restoration work in oil, gas and exploration wells.